Columns

If you are considering strengthening or repairing a concrete, steel or timber column, we invite you to download our specifications and typical details.

Columns in buildings and bridges require strengthening for a wide range of reasons. Depending on the type of material (concrete, steel or timber), the modes of failure and reasons for strengthening vary. In all cases, the patented PileMedic® system offers solutions to repair, restore the original capacity or even strengthen the column beyond its original capacity. This paper offers an overview of the system. Some of the problems that can be fixed using carbon or glass laminates are:

- Increasing flexural strength of columns in seismic regions; this is a major concern in non-ductile concrete frames in seismic regions where the beams are stronger than columns. Flexural hinging in these columns can lead to a sway mechanism and collapse of the building in an earthquake.`

- Increasing the axial capacity of a column due to additional loads from modifications to the building

- Loss of capacity due to corrosion of steel (in concrete and steel columns) or decay of wood in timber columns

- Low-quality (low compressive strength) in concrete columns due to construction errors in the original construction of the column

- Inadequate confining steel (hoop reinforcement) in reinforced concrete columns in seismic regions that leads to low capacity and brittle failure of these columns

Numerous studies funded by various government agencies such as the National Science Foundation, Caltrans, Texas DOT, Nebraska Department of Roads, US Army Corp of Engineers, etc. have proven the effectiveness of the PileMedic® system to repair and strengthen columns. Details of these studies are available here. Our structural engineers will provide designs that enhance axial, flexural and shear capacity of columns. Sealed engineering drawings, calculations and construction documents will be provided to the client.

HISTORY OF DEVELOPMENT

Professor Ehsani’s development of PileMedic® for repair of columns started in the early 1990s where he and his associates at the University of Arizona received a research grant from the U.S. National Science Foundation to study retrofit of bridge columns with carbon and glass FRP. A total of 15 specimens were constructed and tested. The findings of that study were fully detailed in the following three journal articles; it is recommended that those who desire an in-depth understanding of the subject, read these articles that are available on this website:

- Repair of Earthquake-Damaged RC Columns with FRP Wraps By Ehsani, Saadatmanesh and Jin, ACI Structural Journal, March-April 1997

- Seismic Retrofitting of Rectangular Bridge Columns with Composite Straps By Ehsani, Saadatmanesh and Jin, Earthquake Spectra, May 1997

- Seismic Strengthening of Circular Bridge Pier Models with Fiber Composites By Ehsani, Saadatmanesh and Jin, ACI Structural Journal, November-December 1996

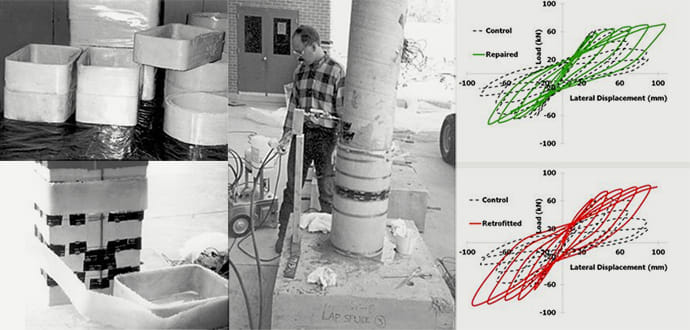

To simulate and understand the behavior of “older” and poorly-designed bridge columns, concrete columns were constructed and tested. Each column was subjected to an axial load of 100,000 pounds. Then the top of the columns was subjected to reverse cyclic loading to simulate the earthquake motion. In the “control” columns that were constructed to simulate the lack of confining ties, after a couple of loading cycles, the column can no longer resist the applied load; this is shown with black dashed lines in the graph where the maximum load at the end of each cycle is less than that at the end of the previous cycle. During these tests, columns suffer significant damage at their base (where the column is connected to the footing).

Engineers are often faced with deciding whether a structure can be repaired and safely put back in service or if it has to be totally abandoned and demolished. Our interest was to show whether such a failed column could be saved by wrapping it with FRP jackets. Such a repair, if successful, could be useful in determining the faith of columns in buildings and bridges that are damaged during an earthquake. All columns in the study were repaired and retested. Repair consisted of removing any loose concrete and packing the void with a concrete mix.

In the early 1990s, since we had not developed the PipeMedic® laminates, we manufactured a somewhat similar but inferior product as shown in the figure below. Unidirectional glass fabric in 6-inch wide bands were saturated with epoxy resin and wrapped several turns around a mandrel representing the shape and size of the column. Mylar sheets were used between the layers to prevent bonding of the saturated fabric to itself. The mandrel and fabric were placed in an oven and cured. Once removed, the result was the laminates that are shown in the photo below.

The laminates were wrapped around the column by brushing a layer of epoxy between the layers to create a multi-layered system. Typically four 6-inch wide bands were epoxy-bonded to the lower 2 feet of the column. Then epoxy resin was injected into the deteriorated column to fill the voids in the concrete. These columns were subsequently tested. The hysteretic (load vs. displacement) response of the repaired specimen is shown in green line. For ease of comparison, the response of the “control” specimen before the repairs is shown in dashed black line. As can be seen, the repaired specimen continues to carry more load with each new cycle of loading. In fact, testing had to be stopped because we reached the maximum pull and push displacement that the testing equipment could provide (+/- 5 inches) without being able to fail this specimen! This test clearly demonstrated the effectiveness of this system for repair of columns that get damaged in an earthquake — making them much stronger than their original undamaged column.

As a part of this study, we also tested a specimen identical to the control one. But in this case, the specimen was retrofitted with FRP bands in a similar manner and tested without any prior testing and damage. This hysteretic response is shown in red. Again, for comparison the response of the control specimen is shown in dashed black line. It is clear that the retrofitted specimen also performs very well — as expected. These tests and others that were a part of that NSF study and are not shown here, clearly attest to the effectiveness of FRP laminates in repair of damaged columns and retrofit of undamaged columns. Our new patented PileMedic® laminates are significantly more efficient than the laminates used in the above study because:

PileMedic® laminates do not need to be custom made to fit a column of particular size and shape; a thin sheet of laminate can be wrapped around columns of any shape or size. This feature not only makes construction scheduling much easier, it also allows these laminates to be used as a fast post-disaster repair system, for example in the immediate hours following an earthquake.

PileMedic® laminates are as wide as 4-ft (compared to the 6-inch wide earlier laminates) and their biaxial reinforcement provides strength in both hoop (confinement) and longitudinal direction (for flexural bending).

The unique construction of PileMedic® laminates also allows us to perform certain repairs (for example repair of submerged piles without the need for divers) that would not be possible with the early generation of laminates we used in the 1990s.

STRENGTHENING FOR AXIAL LOAD CAPACITY

It is not uncommon to encounter columns where due to shoddy construction quality, lower strength concrete was used, compromising the column capacity. In other cases, additional loads on a building may necessitate strengthening of columns. Axial capacity of concrete columns can be increased through confinement of concrete. Wrapping FRP fabric around a column helps a little but that contribution is limited, especially when the column is rectangular.

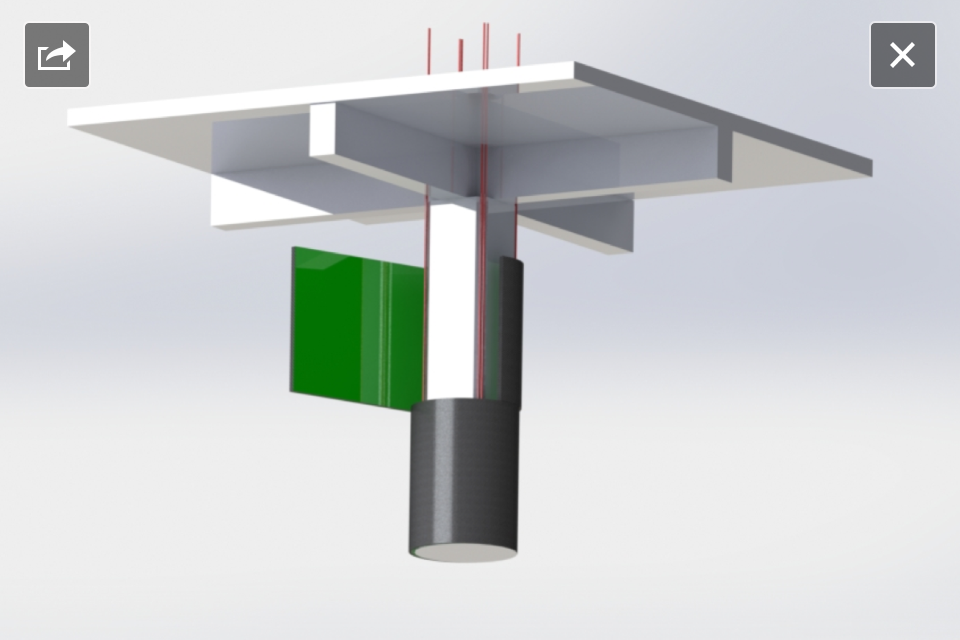

Using PileMedic® laminates, we can create a circular or oval shape shell around the column. This shell can serve as a stay-in-place form that can be filled with concrete and optionally reinforcing bars. The shell provides confinement for the original concrete as well as the newly placed concrete, increasing the compressive strength and thus the axial capacity of the column. These solutions result in compact retrofits that increase the footprint of the column very slightly. For a numerical example of increasing the axial capacity of a concrete column view this paper.

As detailed in the above paper, with a slight increase in the size of the column, PileMedic® carbon laminates can provide significant confinement for a column, especially when the column cross section has been changed to an oval or circular shape and the inefficient corners have been eliminated. These benefits can not be realized if FRP fabric is directly wrapped around. the column.

STRENGTHENING FOR FLEXURAL CAPACITY

Unlike beams, where the maximum bending moments may occur at or near the midspan, the maximum bending in columns is at the supports. It is very difficult and impractical to extend the FRP fabric applied to the surface of the column vertically through the floors above and below.

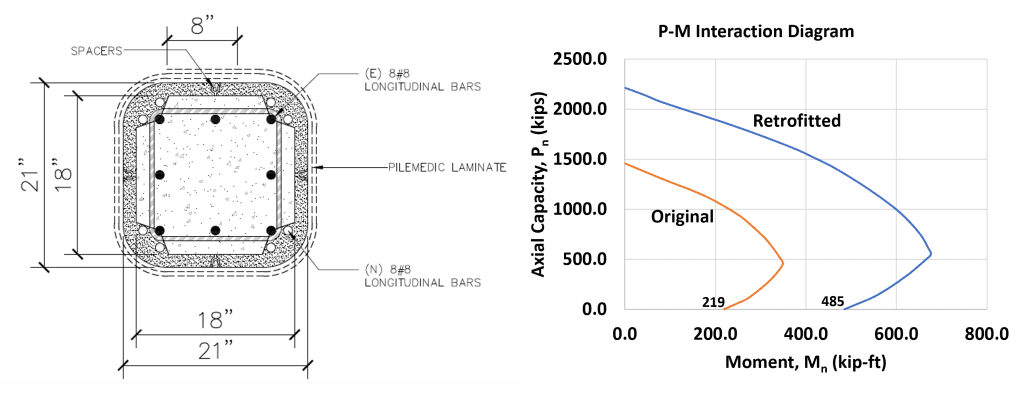

This example here shows a column where new rebars have been added at the corners. PileMedic® laminates have created a stay-in-place form that is filled with concrete. The flexural strength of the column was increased by 220% from 219 to 485 k-ft. with minimal increase in the column size (footprint). The jacket also serves as lateral ties, equivalent to #4 ties at 4 inch spacing along the height of the column. To learn more details about this solution, read this paper.

REPAIR OF CORRODED STEEL COLUMNS

Steel columns in buildings and bridges often corrode; the case shown here is an extreme case in a copper mine where the corrosive environment has resulted in 100% loss of cross section. Ordinary FRP fabrics cannot offer any solution for repair of such columns. However, with the use of PileMedic® laminates, a shell can be quickly created around the column and filled with concrete. Reinforcing bars can also be doweled into the foundation for additional strength. And if necessary, ShearWrap™ or ShearClamp™ can also be utilized to ensure proper load transfer. These repairs are often completed while the structure remains fully in service.

This is a sample project for repair of steel structures in an electrical substation.

SAMPLE PROJECTS

We invite you to watch videos of some of our projects to appreciate the ease of installation of this amazingly versatile product.