In repair of submerged piles, a shell or jacket made with FRP products (such as PileMedic®) is created around the deteriorated pile. This shell is subsequently filled with concrete or grout. A question arises as to how to seal the bottom of this annular space so the grout stays in place. Two conditions can be encountered. In once case, the repair and the jacket extend to the bottom of the seabed. In another case the repair length is limited to the splash zone and a seal must be created along the height of the pile — at some random point. Techniques for both of these options are covered here. We also recommend that you download this installation guide for more detailed instructions.

Sealing at Mud Line

When the extent of the repair goes all the way to the seabed, the bottom of the FRP jacket can be embedded into the soil. The soil in this region is typically soft and silty and it can be easily moved with a high pressure water jet. Most designs call for 6-12 inch of embedment into the soil. Once the soil is pushed out of the way and the jack is positioned, shortly thereafter, the natural movement of the soil at the sea floor will fill the area around the pile jacket and make it flush with the rest of the seabed.

It is always recommended that when filling the annular space, a short layer of grout 6-12 inches (150-300 mm) be placed at the bottom of the annular space and allow some time for this grout to harden. Once the grout is hardened, it acts as a seal at the base of the annular space and it will prevent blowout of any additional grout being placed. Affter several hours, the remaining height of the jacket can be filled with grout. This procedure ensures that there is no blowout at the bottom of the jacket and the weight of the grout will not push the soft silty soil out of the way!

Sealing Along the Pile Height

There are many instances where the repair height does not extend all the way to the bottom of the seabed. In such case, a seal must be created at the elevation of the bottom of the jacket — usually several feet or meters above the seabed floor. Many solutions for such sealing exist and they are described here.

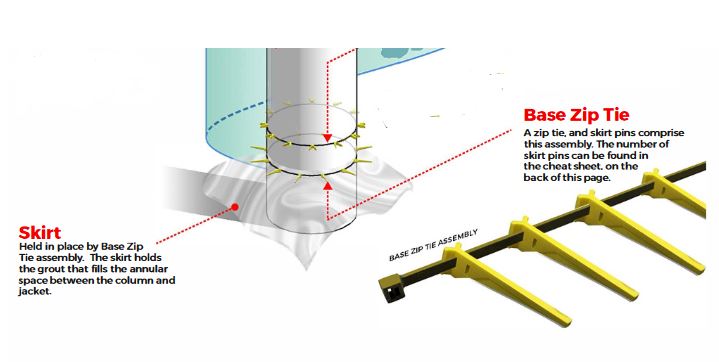

Skirt Pins

PileMedic® Skirt Pins can be used to create a seal at the bottom of the annular space. First, 6 or more Skirt Pins are passed through a zip tie or plastic band. The Skirt itself is made of a long heavy duty plastic sheet pleated along one of the long edges. It is wrapped around the pile and the pleated edge is securely fastened to the pile with the band containing Skirt Pins. At this point, the unpleased edge of. the Skirt is draping loosely. The PileMedic® jacket is placed, resting on the Skirt Pins. Next, foam is shoved into the annular space around the entire perimeter of the annular space. The Skirt is folded over on top of the PileMedic® jacket. Lastly, a zip tie or plastic band is put around the skirt and tightens it securely to the PileMedic® jacket. This creates a “diaper” like bag that will hold the grout in place.

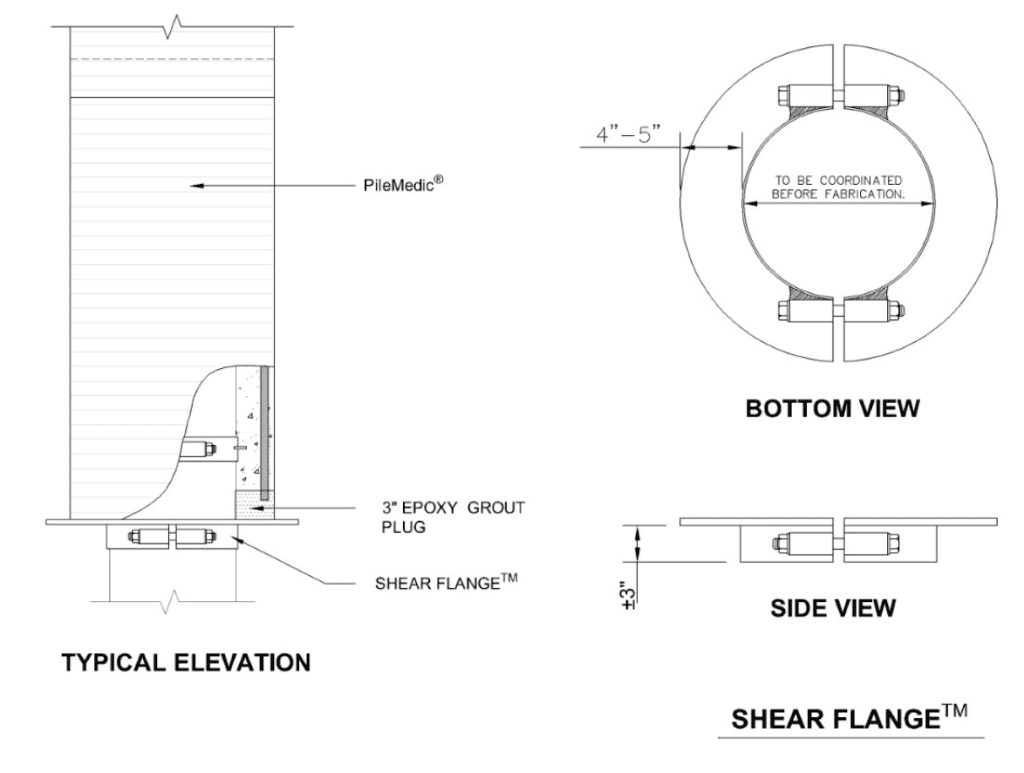

ShearFlange

Another solution is the reusable ShearFlange as shown here. These devices are originally separated into two half rings and once placed around the pile the bolts are loosely connected, allowing the ShearFlange to slide to the desired location. At that time the divers tighten the bolts and the ShearFlange is secured to the pile. The PileMedic® jacket can rest on top of the ShearFlange and once the grout is placed and it hardens, the ShearFlange can be removed and used on other piles.

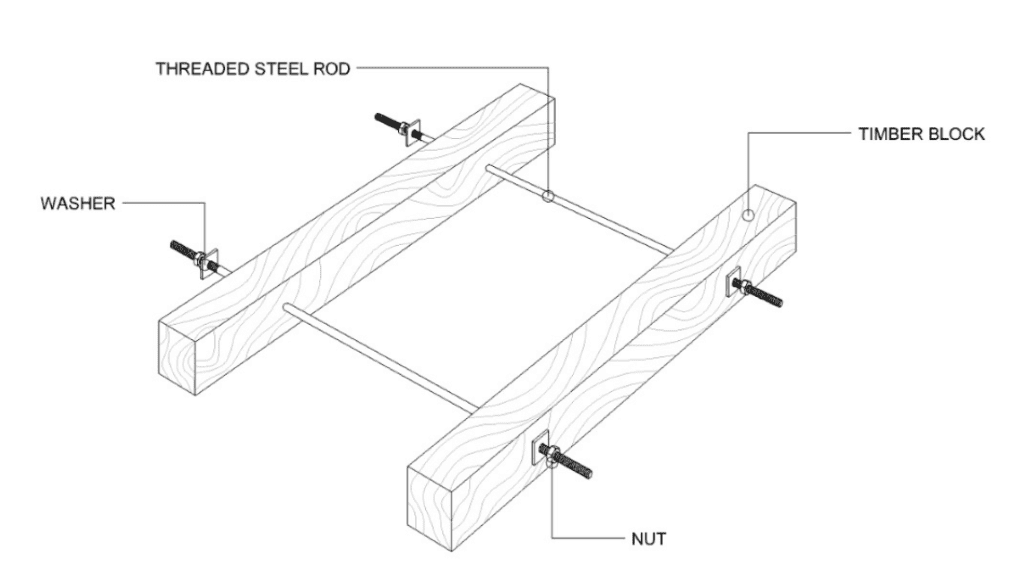

Friction Clamp

Friction clamps are simple devices that can be made locally. Using the threaded rods and nuts, the device is tightly secured around the pile at the desired elevation. Plywood sheets can be cut to match the shape o the pile and these sheets can be secured to the top of the friction clamp. This provides a flat surface that can support the PileMedic® jacket. A foam can be used at the bottom of the annular space to prevent leakage of the grout.