Steel Pipe Pile Repair: Advanced Solutions by PileMedic®

The Industry Leader in Marine Infrastructure Rehabilitation

PileMedic: The Go-To Solution for Steel Pipe Pile Repair

PileMedic® by QuakeWrap offers the most advanced systems for steel pipe pile repair and strengthening, trusted by the US Military worldwide. Our innovative FRP technology delivers superior results for submerged piles, seawalls, and bulkheads with minimal service disruption.

Understanding Steel Pipe Pile Deterioration

Steel pipe piles provide critical foundational support for vital structures including:

- Bridges and overpasses

- High-rise buildings

- Marine piers and docks

- Offshore platforms

- Industrial facilities

Over time, these essential structural elements deteriorate due to:

- Environmental exposure (especially in marine settings)

- Electrochemical corrosion

- Mechanical stresses and impacts

- Section loss that compromises load-bearing capacity

- Biological activity in marine environments

Early detection of these issues is crucial, with warning signs including:

- Visible rust, scaling, or pitting corrosion

- Structural instability or unexpected movement

- Reduced load-bearing capacity

- Cracking or spalling of surrounding concrete

- Water infiltration or erosion around the pile base

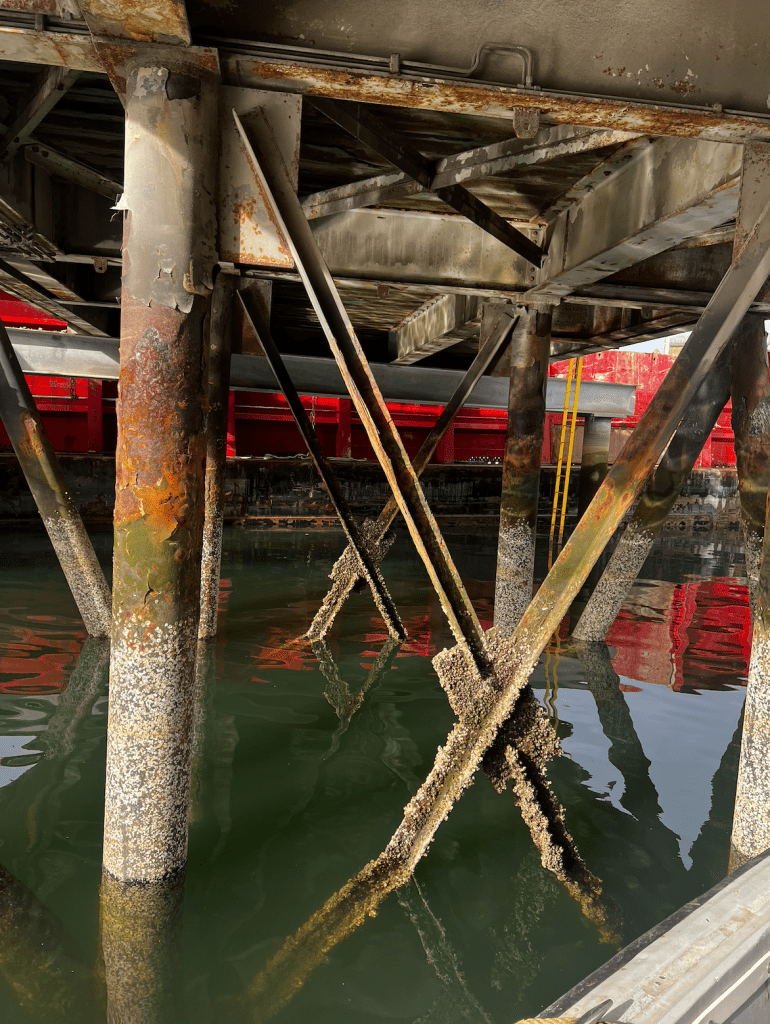

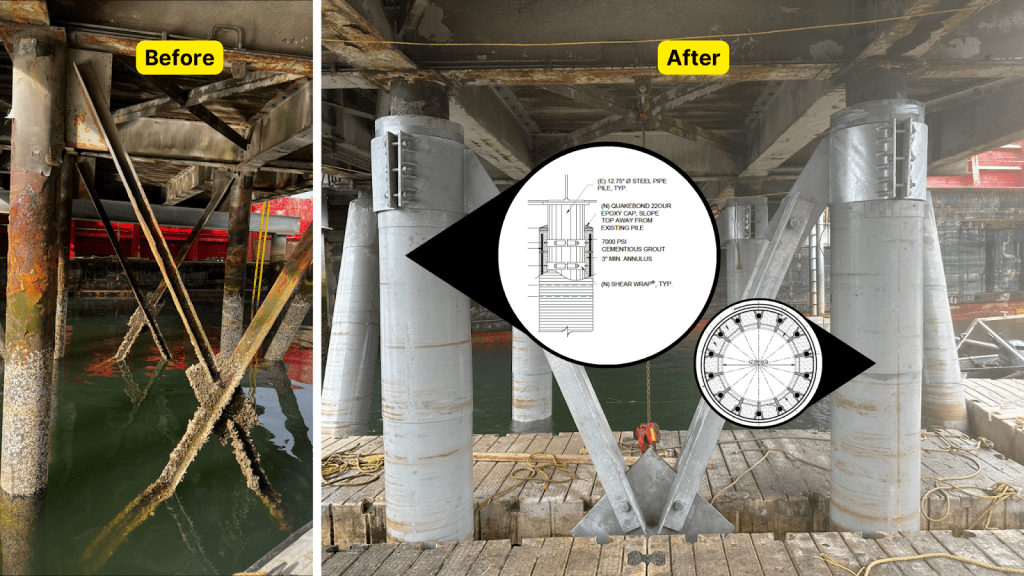

Before

Types of Damage to Steel Piles

Moving on from the discussion of the structure and design of steel piles, it is important to understand the types of damage that can occur to these essential structural elements.

Steel piles are susceptible to different forms of deterioration. Corrosion, resulting from exposure to moisture (dry-wet cycles) and environmental factors, weakens the steel and reduces its load-bearing capacity. Electrolysis can also accelerate corrosion when metals come into contact with each other in the presence of an electrolyte like saltwater.

Fatigue caused by repeated loading and unloading cycles leads to crack formation, further compromising the pile’s strength. Additionally, environmental factors like bacteria, fouling, and harsh weather conditions contribute to pile damage.

Recognizing these types of damage is crucial for implementing appropriate repair methods that restore their structural integrity and ensure their continued functionality.

Advanced PileMedic® Steel Pipe Pile Repair Solutions

Revolutionary PileMedic® System

Our patented PileMedic® system utilizes high-strength FRP laminates to restore and enhance the structural capacity of deteriorated steel pipe piles. The process creates a seamless protective shell that:

- Installs rapidly with minimal downtime

- Restores original structural strength

- Significantly increases load-bearing capacity

- Provides superior corrosion protection

- Extends service life by decades

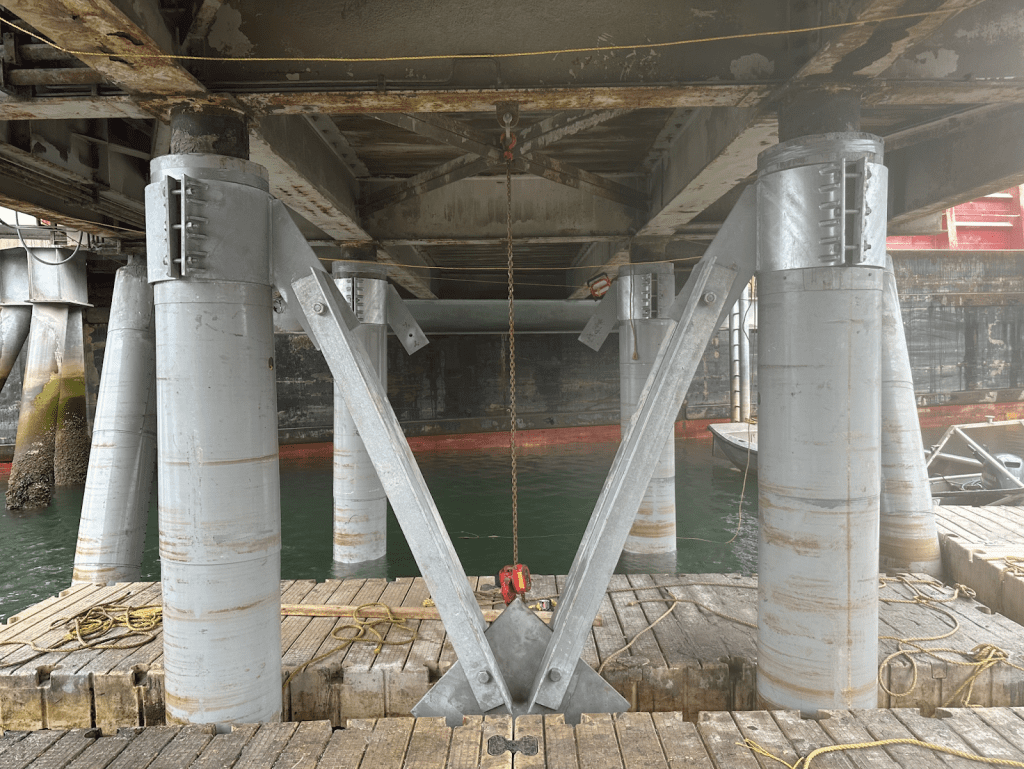

After

Looking for Help with your Project?

Schedule a Call

Get free advice for any upcoming projects or repairs

See Specs and Sample Designs

Get full specs and details to plan out your next project

Common Challenges in Steel Pipe Pile Repair

Access Difficulties

Piles in marine environments, offshore structures, or beneath existing buildings present significant access challenges. Our specialized equipment and techniques effectively address these complexities.

Environmental Conditions

Factors like water salinity, temperature variations, and biological activity accelerate deterioration. Our repair systems are specifically designed to perform in these harsh environments.

Load Management

Repairing damaged piles without disrupting operations requires precise engineering. Our solutions maintain structural integrity throughout the repair process.

Regulatory Compliance

Our repair methods meet strict environmental and safety regulations, ensuring your project proceeds without unnecessary delays.

Innovative ShearWrap™ Technology

ShearWrap™ is our patented solution designed specifically for steel pipe piles with severe section loss. This revolutionary system:

- Facilitates effective shear transfer without welding

- Creates a continuous load path that bypasses corroded regions

- Eliminates the need for hot work permits in marine environments

- Provides tensioned steel bands that enhance friction and load transfer

- Delivers cost-effective repair without complete pile replacement

Learn more about ShearWrap™ here.

The PileMedic® Advantage for Steel Pipe Pile Repair

Choosing PileMedic® for your steel pipe pile repair project delivers measurable benefits:

- Lightweight & High-Strength: Our FRP materials provide exceptional strength without adding unnecessary weight

- Rapid Installation: Prefabricated jackets and wraps enable fast application with minimal service disruption

- Long-Term Durability: Resists environmental degradation for decades of maintenance-free performance

- Versatility: Customized solutions for various pile shapes, diameters, and environmental conditions

- No Welding Required: Eliminates costly and hazardous underwater welding operations

See how to repair a steel pile here.

Cost-Effective Solutions

Our steel pipe pile repair systems deliver excellent ROI by:

- Minimizing operational downtime during installation

- Eliminating the need for complete pile replacement

- Reducing long-term maintenance requirements

- Extending the service life of existing infrastructure

- Providing comprehensive solutions for severe structural damage

Case Study: The Seattle Project

The Challenge

A major facility in Seattle faced severe corrosion and section loss in its steel pipe pile foundation, threatening the stability of mission-critical operations.

QuakeWrap’s Solution

Our team designed an advanced repair system incorporating:

- PileMedic® laminates for structural restoration

- ShearWrap™ technology to ensure continuous load path

- Vertical reinforcing bars to enhance load-bearing capacity

- Redesigned braces to fully restore structural integrity

Results

- Completely stabilized infrastructure without operational interruption

- Fully restored structural integrity of severely damaged piles

- Exceeded client expectations for long-term performance

- Prevented catastrophic facility shutdown

Marine Infrastructure Live: Steel Pipe Pile Repair

Frequently Asked Questions About Steel Pipe Pile Repair

Steel pipe pile repair presents various challenges, including corrosion and material degradation, difficult access in marine environments, structural load management during repairs, and regulatory compliance requirements.

PileMedic® offers significant advantages including lightweight yet high-strength materials, quick installation with minimal disruption, long-term durability without maintenance, and versatility for various pile configurations.

ShearWrap™ is a patented device that facilitates the transfer of loads without requiring welding. It uses tensioned steel bands around the pile to enhance friction and create a continuous load path that bypasses corroded regions.

Our solutions are ideal for marine and offshore structures, industrial facilities, bridges and transportation infrastructure, and commercial buildings supported by steel pipe piles.

Warning signs include visible corrosion, structural instability, reduced load capacity, cracking of surrounding structures, and water infiltration. We recommend regular professional inspections to identify issues early.

More Videos on Pile Repair

Advantages of ShearWrap™ and ShearClamp™

ENGINEERING

Engineered solution for direct load path.

PROJECT SPECIFIC

Customizable for project specific steel pile and column sizes.

WELD-FREE REPAIR

No welding or drilling of existing structural member.

ABOVE AND BELOW WATER REPAIR

Easy installation for divers for below water repair.

CIRCULAR OR H- PILE REPAIR

Provides load transfer around repair zones for original circular or square piles and columns.

INTEGRATION

Specially designed and easily integrated into the PileMedic® marine pile and column repair system.