ShearWrap™ and ShearClamp™

ShearWrap™ and ShearClamp™ are patented (US Patent #11286632) prefabricated devices that are used in repair of steel piles. When the host pile is made of concrete or timber, the rough surface of the host pile bonds well to the new concrete shell being cast, allowing the host pile and the new concrete shell to work together. However, when the pile is made of steel, there is not sufficient bond between the host pile and the concrete shell. In fact, the AISC design guidelines for composite construction columns for concrete-filled tubes (CFTs) and encased composite columns also known as steel-reinforced concrete (SRC) columns limit the bond stress between steel and concrete to 60 psi (0.40 MPa). To improve this bond, shear studs can be welded to the surface of the steel pile. However, welding under water is costly. In some projects, welding or hot works may be forbidden altogether. In such cases, ShearWrap™ and ShearClamp™ offer a unique solution. These products are designed and manufactured for each project using steel plates and ASTM-designated high-strength bolts.

ShearWrap™ is specially designed for installation on circular steel piles and columns, while ShearClamp™ is specifically designed for installation on steel H piles or wide-flange shaped steel columns. These products are used as part of the PileMedic® structural repair system for steel piles and they will be designed by QuakeWrap engineers for each project. Both ShearWrap™ and ShearClamp™ will be fully embedded in the concrete shell being cast and will not be exposed to the elements or water once the repair is complete.

This video shows how ShearWrap™ and ShearClamp™ are made at QuakeWrap’s manufacturing facilities.

ShearWrap™ for Circular Steel Pile Repair

ShearWrap™ is a patented device for transfer of loads from the newly cast concrete around the pile to the deteriorated pile. These devices are manufactured specifically for each project. They consist of two half bands of steel that get connected together with two high-strength bolts to create a full circular ShearWrap™. The wraps are loosely placed around the pile and can slide up and down to the correct elevation. At that point the two bolts are tightened to the predetermined torque. This tension force results in very large normal stresses between the surface of the ShearWrap™ and the host pile, increasing the friction between these two surfaces. Each ShearWrap™ can resist a certain designed shear force through friction. In some cases, additional wings or flanges can be welded to the ShearWrap™ to increase its capacity. The ShearWraps™ get embedded in concrete (or grout).

As shown in the animation, the load is applied to the steel pile and the groups of ShearWrap™ are installed both above and below the deteriorated (corroded) or missing portion of the pile. When the load reaches the upper groups of ShearWrap™, it is transferred from the pile to the concrete (or grout) shell. The load will pass through the concrete shell, bypassing the deteriorated region of the steel pile until it reaches the lower set of ShearWraps. At that point, the load will transfer back into the steel pile.

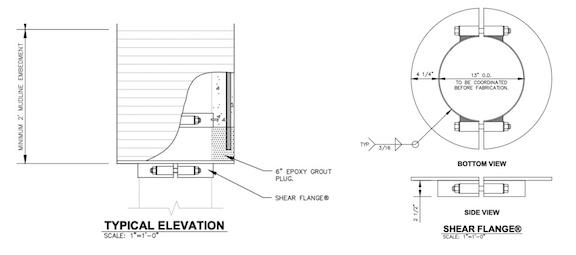

ShearFlange™ for Support

A variation of ShearWrap™ is the ShearFlange™ described here. These devices have a wide ring (platform) at the top. They can be fastened temporarily around a circular pile to support the PileMedic® shells and to create a seal at the bottom of the annular space. Once the grouting operation is complete and the grout has hardened, the ShearFlange™ can be removed and used on other piles being repaired.

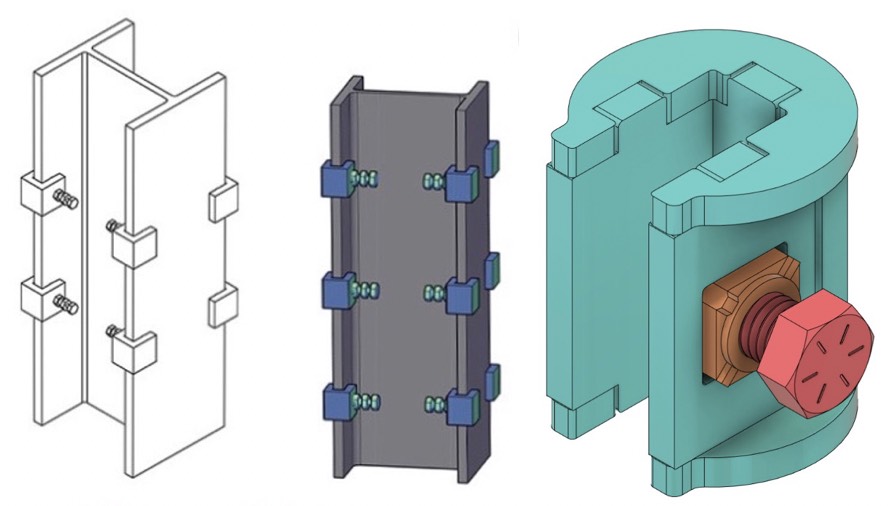

ShearClamp™ for H-Piles

Similar to ShearWrap™ described above, the load transfer around repair zones of steel H-piles or columns is achieved using ShearClamp™. As shown in this video, these units are individually attach dot the flanges of steel pickling and columns and are tightened to the prescribed torque value. The combination of friction (generated by the tightening of bolts) and bearing capacity (based on the projected area of the device in plan view) determine the capacity of each ShearClamp™ in transferring loads.

QuakeWrap engineers will design ShearClamp™ and the required quantities and placement of the units for each project.

Installation

The two halves of ShearWrap™ are loosely placed around the corroded circular steel pile. At this stage the bolts are loose and allow for sliding of ShearWrap™ up and down the height of the pile. Once the device is at the prescribed location (above or below the Beverly corroded zone), the bolts are tightened to the prescribed torque value.

Once all ShearWraps are installed, spacers and GFRP reinforcing bars are placed and the entire assembly gets wrapped in PileMedic® jackets. At this point the bottom of the annular space is sealed and the annular space is filled with grout.

Advantages of ShearWrap™ and ShearClamp™

ENGINEERING

Engineered solution for direct load path.

PROJECT SPECIFIC

Customizable for project specific steel pile and column sizes.

WELD-FREE REPAIR

No welding or drilling of existing structural member.

ABOVE AND BELOW WATER REPAIR

Easy installation for divers for below water repair.

CIRCULAR OR H- PILE REPAIR

Provides load transfer around repair zones for original circular or square piles and columns.

INTEGRATION

Specially designed and easily integrated into the PileMedic® marine pile and column repair system.