Piles, the essential support structures for foundations, bridges, and piers, can suffer from various issues such as corrosion, deterioration, aging, cracking, or damage due to marine environments. These problems compromise the structural integrity and load-bearing capacity of piles.

Therefore, effective pile repair methods are crucial to restore their functionality and ensure the stability and safety of supported structures. This article explores common pile repair techniques employed for different types of piles including concrete, timber, and steel piles.

Protective coatings or jackets can be added to prevent further deterioration in some cases while grout or resin injection strengthens weakened piles. Additionally, damaged sections may require replacement using pile driving or splicing techniques. The techniques presented here can restore the full capacity of an existing pile even when there is 100% section loss without the need to provide a new pile!

Dynamic testing and non-destructive tests such as measurement of loss of wall thickness in a steel pile are important tools used to assess the condition of damaged or weakened pilings accurately. By understanding these pile repair methods, engineers can effectively diagnose issues and implement appropriate solutions to prolong the lifespan of piles and ensure the long-term stability of structures they support.

Looking for Help with your Project?

Schedule a Call

Get free advice for any upcoming projects or repairs

See Specs and Sample Designs

Get full specs and details to plan out your next project

Common Types of Pile Repair

One important aspect of pile repair is understanding the common types of pile repair methods, which can help in effectively restoring the structural integrity and load-bearing capacity of damaged piles.

Pile evaluation plays a crucial role in determining the appropriate repair technique. Dynamic pile testing is often used to assess the condition of the piles and identify any underlying issues.

One commonly used method for repairing damaged piles is the fabric pile jacket. This involves wrapping a high-strength fabric around the damaged pile and injecting grout or epoxy into it to provide additional strength and support.

Another method is pressed pile construction, where new piles are installed adjacent to the damaged ones to transfer load and reinforce the foundation.

Concrete damage repair techniques, such as epoxy injection, are also employed to address issues like cracking or corrosion in concrete piles.

The most common type of repair for piling is to encapsulate the damaged pile or column in a shell or jacket and fill the annular space between this shell or jacket with a filler material such as epoxy grout or underwater cementitious grout. In some case, additional reinforcing bars can also be placed in the annular space for further strengthening of a deteriorated pile.

These various approaches are implemented depending on factors such as the type and extent of damage, budget constraints, and project requirements in different pile repair projects.

Concrete Piles

This discussion will focus on the structure and design of concrete piles, the types of damage that can occur to them, and the methods used for repairing concrete piles.

Concrete piles are commonly long cylindrical or square structures made of concrete that are driven deep into the ground to support structures. Other cross sections, such as hexagon or octagon are also used in some projects. They come in three main types: cast-in-situ bored piles, precast or driven piles, and post-tensioned piles.

Damage to concrete piles can occur due to factors such as corrosion, deterioration, cracking, or external accidents.

Repairing damaged concrete piles involves identifying the cause and extent of the damage and implementing appropriate repair techniques to restore their structural integrity and load-bearing capacity.

Structure and Design of Concrete Piles

Concrete piles are designed to transfer loads from the superstructure to deeper soil or rock, ensuring adequate bearing capacity and minimal settlement or lateral movement. They can be made of concrete, steel, or wood and installed through driving, drilling, or jacking methods.

The design of a concrete pile involves determining the type, size, depth, and number of piles needed to support the load without excessive deformation. Pile groups are used when axial loads on the column are heavy. Reinforcement with steel bars is commonly employed in concrete piles to enhance their strength and ductility. In some cases, prestressing of the piles using high-strength steel cables is used.

Pile repair methods for broken piles include using pile cylinders or jackets to encase the damaged area and restore its structural integrity. Another method is the pressed pile method, where hydraulic jacks are used to lift and stabilize a sunken or settled pile pier. These techniques help maintain the load-bearing capacity of concrete piles and ensure their long-term performance.

Types of Damage to Concrete Piles

Fractures and cracks can manifest in various forms, ranging from hairline fissures to extensive breaks, illustrating the diverse types of damage that concrete piles can incur. The following are some common types of damage to concrete piles:

- Fractures and cracks: These can occur due to factors such as overloading, dynamic loads, and chemical attack. These cracks can be classified as longitudinal, transverse, diagonal, or radial depending on their direction.

- Cracks in concrete piles allow penetration of seawater that accelerates the corrosion of reinforcing steel; this leads to further cracking and spalling of the concrete that results in significant loss of strength in the concrete pile.

- Mud intrusion: Soil or mud entering the pile during construction weakens it and reduces its load-bearing capacity. This issue is more prevalent in marine environments.

- Secondary concrete pouring: When new concrete is poured around an existing pile, it can cause damage due to the weight and pressure exerted on the original pile.

- Voids and inconsistency in concrete mix: These issues occur during the construction process and weaken the pile by creating honeycombs, cavity or hollow spaces or areas with inadequate strength.

- Geometric errors: Manufacturing or installation errors can result in misaligned or structurally compromised piles.

- Spalling near the pile head: High stress near the head of a pile caused by insufficient cushioning or poor hammer performance can lead to spalling or chipping of concrete near the top surface.

Methods for Repairing Concrete Piles

One approach to restoring the structural integrity of deteriorated concrete columns involves the application of carbon fiber reinforcement. This method is a widely used and successful column repair technique. However, the technique is not that effective when repairing piles that are submerged in water.

The patented PileMedic technology uses high-strength thin laminates made with carbon or glass FRP that are supplied in 4-ft wide rolls. In the field, these laminates are cut to desired lengths, which is typically twice the perimeter of the pile plus 8 inches (200mm).

Proprietary spacers are connected around the column or pile using zip-ties. Longitudinal reinforcing bars are snapped into place; it is preferred to use non-metallic GFRP rebars that will not corrode.

The PileMedic laminate is coated with epoxy and is wrapped tightly around the spacers to create a 2-ply shell around the column or pile. Additional 4-ft tall shells can be similarly installed, overlapping the previous shell by 4 in. (100mm).This process is continued until the desired height of the pile is covered.

The annular space between the shell and the pile or column is filled with underwater grout or concrete. The PileMedic jacket is equivalent to #4 ties at a spacing of 3 inch (75mm) along the height of the pile. This eliminates the need for providing ties around the longitudinal bars and drastically reduces construction time.

The laminates also create an impervious shell around the pile or column, keeping all moisture and oxygen away from the pile. Because oxygen is the fuel to the corrosion process, this repair technique that deprives the pile of access to oxygen, significantly reduces the corrosion rate.

In most ase, the new reinforced concrete shell can be designed to resist all loads independently of the original deteriorated pile.

By applying this method, savings in pile repair costs can be achieved compared to outdated piling repair methods such as complete removal and replacement. Additionally, this repair method can be applied to various types of concrete piles, including those found in bridge pilings and piers, foundations, corroded columns in buildings in coastal regions such as Florida, utility poles and similar repair projects.

Combined with other techniques such as using high-strength epoxies for enhanced durability and performance, this repair technique offers a wide range of engineered solutions for practically all types of repair scenarios.

Timber Piles

Timber piles are structural elements used to support piers and other structures, typically made of wood or concrete. The structure and design of timber piles can vary depending on factors such as the type of wood used and the load-bearing requirements.

Types of damage that timber piles can experience include decay, insect infestation, splitting, and erosion.

Repair methods for timber piles may involve treatments such as preservatives or coatings to prevent further deterioration. However, considering their environmental impact, these techniques are rarely used. Other repair techniques involve encasement in a shell made with FRP that is filled with resin or cementitious grout.

Structure and Design of Timber Piles

The diameter and length of timber piles are carefully considered during their design, with the diameter typically ranging from 10 to 16 inches and the length being 20 times the top diameter, creating a proportional and sturdy foundation resembling towering tree trunks.

To ensure durability, timber piles used to be treated with preservatives due to their susceptibility to decay and insect damage. However, in recent years, environmental concerns have significantly reduced the use of treated wood. This has resulted in much faster decay and deterioration of timber piles in a marine environment.

The quality of timber piles is determined by factors such as species, moisture content, knots, and splits. These factors play a crucial role in determining the precise pile capacity and overall structural integrity of the timber pile.

Understanding the structure and design of timber piles is essential when considering pile repair methods for common damage defects or when undertaking a pile pier repair job or other foundation repair solutions.

Types of Damage to Timber Piles

In the previous subtopic, we discussed the structure and design of timber piles. Now, let’s explore the various types of damage that can occur to timber piles.

Timber piles are susceptible to several forms of damage, including decay, rotting from dry-wet cycles, marine borer infestation, sustained loading effects, and impact damage. Decay is caused by organisms and can lead to structural deterioration over time. Marine borers also pose a threat to timber piles in marine environments. Sustained loading can result in microscopic mechanical damage if the pile is loaded close to its ultimate capacity for an extended period.

Additionally, impact damage may occur due to accidents or external factors such as construction activities. These damages can manifest as cracks or fractures in the timber pile.

To provide further insight into these types of damage and their implications for repair methods, the following table summarizes key information:

| Type of Damage | Causes | Implications |

| Decay | Organisms | Structural deterioration |

| Decay | Dry-wet cycle | Structural deterioration and loss of capacity |

| Marine Borer Infestation | Marine environment | Weakening of pile structure |

| Sustained Loading Effects | High load over a long duration | Microscopic mechanical damage |

| Impact Damage | Accidents or external factors | Cracks or fractures in the pile |

Understanding these types of damages is crucial when selecting appropriate repair techniques for timber piles. By identifying the specific type and extent of damage, marine engineers repair companies or contractors can determine the most suitable approach to restore structural integrity with minimal cost and quick turnaround time. Encasement of timber piles in a concrete shell offers benefits such as resistance against decay and marine borers while providing a reliable solution against impact damage.

Methods for Repairing Timber Piles

The most popular method of repair of piles which was extensively tested by the US Army Corps of Engineers, involves attaching spacers and GFRP reinforcing bars to the pile, encasing the pile in PileMedic jackets, and filling the annular space with grout. As shown here, this technique can be used even when a section of the pile is missing. The GFRP rebars will span across the missing portion and concrete will be used to make up for the missing wood/timber pile.

The new reinforced concrete pile being cast around the decayed timber pile will be stronger than the original pile. Thus, the full capacity of the pile with a missing section can be restored.

This technique has been tested extensively over three years by the Army Corps of Engineers. The test results are available here. Based on these tests, PileMedic is the only solution approved for the use of the military worldwide. The ease of installation and the fact that no advanced knowledge of the size and shape of the pile to be repaired are necessary were among the reasons that the USACE selected PileMedic as its standard repair system.

The photo shows the final day of the testing and approval for PileMedic that was held at Sandy Hook, NJ. A timber pile encased in PileMedic jacket is displayed while the dive team demonstrates how a pump can be used with the PileMedic grout port to fill the annular space with a cementitious underwater grout.

Another repair solution we offer results in virtually no enlargement of the pile. In this technique, the PileMedic laminate is tightly wrapped around the timber pile to create a snug-fitting jacket. Next, the small annular space between the shell and the pile is filled with our low-viscosity resin. This epoxy is gravity-fed and it fills all the voids and cracks in the wood, resulting in significant increase in the axial capacity of the pile. The epoxy also bonds the PileMedic shell to the timber pile, increasing the flexural strength of the pile.

We have strengthened many timber utility poles with the same technique. In some cases, the old timber pole was made to become stronger than a new steel pole! This saves the power utility companies significant time and money and drastically reduces downtime or disruption of service to the customers.

Overall, comprehending the different forms of damage that can affect timber piles allows for informed decision-making during pile repair processes.

Steel Piles

This discussion will focus on the structure and design of steel piles. Steel piles are typically one of two shapes: H-piles or cylindrical (pipe) piles. The latter may be hollow or filled with concrete. In either case, they are designed to provide structural support and load-bearing capacity in various construction projects.

Damage to steel piles can occur due to factors such as corrosion, fatigue, or impact from external forces. Repair methods for steel piles may involve techniques such as welding or patching damaged areas, reinforcing with additional materials, or installing protective coatings to prevent further deterioration.

Structure and Design of Steel Piles

The structure and design of steel piles play a crucial role in ensuring the stability and load-bearing capacity of foundations and structures supported by them. Here are some key points regarding the structure and design of steel piles:

1) Slab Foundations: Steel piles are commonly used in supporting slabs or foundations. The design of steel piles takes into account the specific requirements of slab foundations.

2) Driven Piling: Circular or H-shaped Steel piles are typically driven into the ground, with a portion of the piling remaining above the surface. This exposed portion allows for connections to other structural elements or for resectioning if necessary.

Types of Damage to Steel Piles

Moving on from the discussion of the structure and design of steel piles, it is important to understand the types of damage that can occur to these essential structural elements.

Steel piles are susceptible to different forms of deterioration. Corrosion, resulting from exposure to moisture (dry-wet cycles) and environmental factors, weakens the steel and reduces its load-bearing capacity. Electrolysis can also accelerate corrosion when metals come into contact with each other in the presence of an electrolyte like saltwater.

Fatigue caused by repeated loading and unloading cycles leads to crack formation, further compromising the pile’s strength. Additionally, environmental factors like bacteria, fouling, and harsh weather conditions contribute to pile damage.

Recognizing these types of damage is crucial for implementing appropriate repair methods that restore their structural integrity and ensure their continued functionality.

Methods for Repairing Steel Piles

Different techniques can be employed to restore the structural integrity and load-bearing capacity of steel piles that have suffered damage or deterioration. These methods include welding, steel jacketing, and concrete encasement.

- Welding: This technique is used for repairing both steel pipe piling and steel sheet piling. It involves cutting out the damaged section and splicing in a new section of piles. However, welding underwater is very costly, and in many sites, the presence of flammable chemicals forbids the use of hot work.

- Steel Jacketing: Damaged steel piles can be reinforced by encapsulating them in a new steel jacket. This additional layer provides extra support and strength. But these repairs also require underwater welding which may not be permitted on the job site.

- Concrete Encasement: Corroded or damaged steel piles can be repaired by encasing them in a PileMedic jacket that is filled with concrete and reinforcing bars.

Bond Transfer in Steel Piles

When concrete or timber piles are repaired by adding a ring of reinforced concrete around the host pile, the rough surface of those piles allows for the loads to be transferred from the host pile to the newly cast reinforced concrete ring. However, in steel piles, there may be insufficient bond between the surface of the corroded steel pile and the freshly cast concrete.

One way to address this issue is by welding shear studs or shear connectors to the old pile. However, when the pile is corroded, welding may not be feasible. Moreover, many industrial projects do not allow welding on the job site.

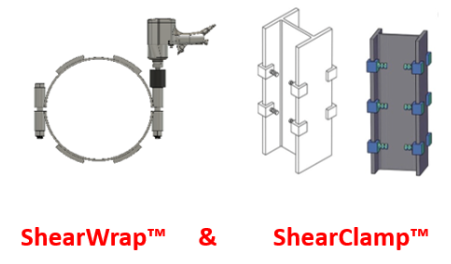

We have recently developed a patented system called ShearWrap and ShearClamp. These custom-made devices are manufactured with steel and they are tightly fastened (torqued) to the old steel pile. Using the principles of friction, these elements can transfer the load between the old pile and the new concrete ring.

Frequently Asked Questions

Common causes of damage to piles include corrosion, deterioration, cracking, or external factors like marine environments and accidents. Identifying the cause and extent of damage is crucial for implementing appropriate pile repair methods to restore structural integrity.

Assessing the extent of damage in piles involves a systematic evaluation process. This includes visual inspections, non-destructive testing techniques (e.g., ultrasonic testing), measurement of loss of wall thickness in steel piles, and load testing to determine the structural integrity and load-bearing capacity of the damaged piles.

Yes, there are environmentally friendly pile repair methods available. These methods include techniques such as cathodic protection, fiber-reinforced polymer (FRP) wrapping, and injection with grout or epoxy. They aim to minimize environmental impact while effectively restoring the piles’ structural integrity.

Damaged piles can be repaired without disrupting surrounding structures through various techniques such as jacketing, underpinning, etc. The patented system provided by PileMedic can restore the full capacity of piles even if 100% loss of cross section has taken place. This technique restores the structural integrity of the piles while minimizing disturbances to the surrounding environment, and in most cases allowing the port to remain in service.

The typical costs associated with pile repair vary depending on factors such as the size (diameter) of the pile, extent of damage, type of piles, and repair method employed. Costs can include materials, labor, equipment, engineering fees, and any required permits or inspections. At PileMedic, we can provide an estimate for the repair of your project that includes all of the above components, including installation.