Tired of dealing with corrosion and decreased load capacity in your marine structures? Say goodbye to pile failures with pile jackets.

These innovative solutions provide long-lasting protection, addressing issues like deterioration. Our solution, the PileMedic jacket works for all forms of pile jacketing, from timber to concrete piling.

With various filler materials available, the jacket’s suitability is determined by the specific design application. Cathodic protection pile jackets are highly recommended in areas with high salinity, using electrical charge to stop corrosion and enhance durability.

Key Benefits and Features

- Corrosion Protection: Pile jackets serve as a barrier in the harsh marine environment, preventing corrosion and extending the service life of marine structures constantly exposed to saltwater and other corrosive elements.

- Eliminating Ties: PileMedic jackets serve as a continuous lateral tie around the pile, equivalent to #4 steel ties at a spacing of 3 inches (depending on the type of laminate and number of layers). The elimination of steel ties makes the repair much easier, requiring a single diver to snap the vertical rebars into the spacers.

- Custom Sizing: Pile jackets are custom-sized for each individual structure, ensuring a perfect fit. This enhances their effectiveness and eliminates potential project delays caused by incorrect sizing.

- High-Quality Materials: Pile jackets are made from high-quality raw materials carefully selected for their durability and resistance to corrosion. This ensures that the jackets can withstand the harsh marine conditions and maintain their protective qualities.

- Increased Load Bearing Capacity: Pile jackets reinforce structures, allowing them to support heavier loads and preventing potential structural failures. This makes them an essential component for marine structures requiring piling for support.

Applications

Pile jackets have a wide range of applications in marine engineering and are commonly used to protect and reinforce various types of piling structures. Here are four key applications of pile jackets:

- Pier and Wharf Rehabilitation: Pile jackets are commonly employed to repair and reinforce piles supporting piers and wharves, which are constantly exposed to harsh marine conditions and may suffer from corrosion or degradation over time.

- Bridge Support Repair: Marine bridges often utilize pilings for support. Pile jackets are used to repair and strengthen these pilings, especially in areas where the structures are vulnerable to corrosion due to saltwater exposure.

- Offshore Platforms: Pile jackets are utilized for the repair and maintenance of pilings in offshore structures, such as oil rigs, jetties, or platforms where the pilings are subject to corrosive seawater and environmental stress.

- Seawall and Bulkhead Restoration: Seawalls and bulkheads that protect coastal areas are subject to constant exposure to seawater. Pile jackets are used to repair and reinforce the supporting piles, preventing corrosion and enhancing their structural integrity.

- Dock and Marina Repairs: Pile-supported docks and marinas often require repairs due to the corrosive effects of saltwater. Pile jackets are utilized to protect and strengthen the pilings, ensuring the safety and longevity of these structures.

- Harbor Infrastructure Maintenance: Pile jackets play a significant role in maintaining the structural integrity of various harbor installations, such as dolphins, fenders, and other marine infrastructure elements supported by pilings.

With their versatility and effectiveness, pile jackets are essential in marine engineering projects. Now that you understand the various applications of pile jackets, let’s dive into the next section and explore the process of pile jacket installation.

Pile Jacket Installation

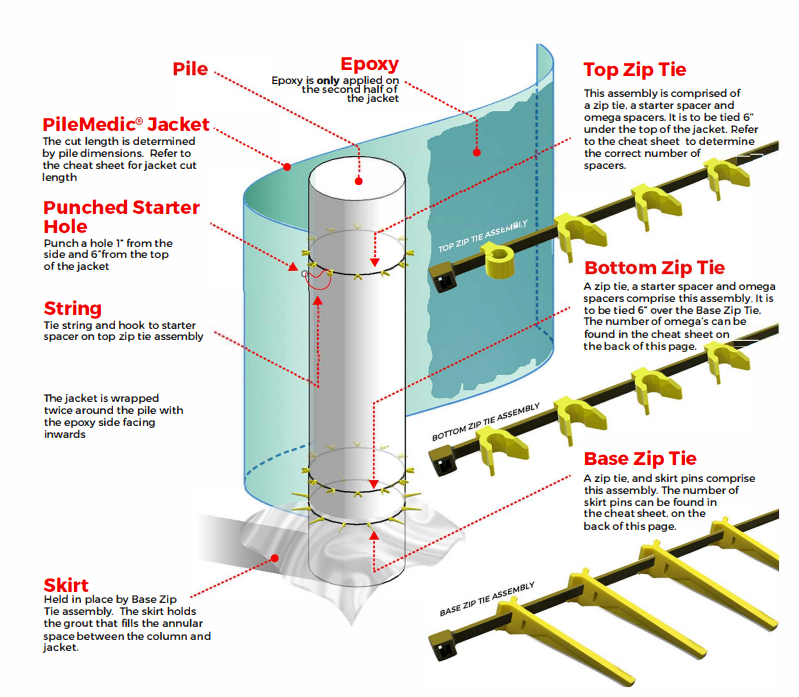

When installing, it’s important to carefully follow the steps and guidelines to ensure proper protection and reinforcement of piling structures.

The first step in the installation process is to excavate the sea floor to allow for the installation over at least one foot of sound pile. This provides a solid substrate for the jacket.

Once the sea floor is excavated, the pile should be cleaned to create a clean and solid surface for the jacket to adhere to.

Next, reinforcing steel and stand-offs should be installed where necessary. This helps to strengthen the pile and provide additional reinforcement.

After the reinforcing steel is in place, the jacket can be hung from the suspender ring. It’s then zipped closed and secured at the bottom to ensure a snug fit around the pile.

To ensure the longevity of the pile jacket, it’s important to properly inject mortar through two hoses that extend to the bottom of the jacket. This helps to fill any voids and ensure that the jacket is fully sealed and reinforced.

By carefully following these installation steps, you can ensure that the pile jacket will provide the necessary protection and reinforcement for the piling structure.

Now that we’ve covered the installation process, let’s move on to discuss the assets of pile jackets.

Pile Jacket Assets

Please take a look below at some of the assets we have for more information and real-world work using pile jackets.

Product Downloads

Pile Repair Kit

PileMedic at a Glance

PileMedic Applications

Case Studies

Frequently Asked Questions

A pile jacket typically lasts for a considerable amount of time before needing replacement. The exact lifespan can vary depending on factors such as the type of jacket, environmental conditions, and maintenance practices.

To maintain pile jackets, regular inspections and cleaning are necessary. Inspect for any signs of corrosion or damage and clean off any marine growth or debris. Repair or replace damaged jackets promptly to ensure continued protection and structural integrity.

Pile jackets can be installed on both existing structures and new construction. They provide corrosion protection, arrest deterioration, and increase load bearing capacity.

Yes, there are limitations on the types of pile materials that can be jacketed. Timber, pipe, concrete piling, and I-beam wraps are typical applications. The suitability of filler materials like concrete, grout, and epoxy depends on the design application.

When considering the installation of pile jackets, it is important to take into account any environmental considerations or regulations that may apply. These could include restrictions on certain materials or guidelines for protecting marine ecosystems during the installation process.