Proposing earth dam overtopping prevention with SPiRe+

Dam safety is paramount to prevent catastrophic consequences associated with dam failure. This article presents an innovative solution to one of the most critical challenges facing earth dams today: overtopping prevention through the revolutionary SPiRe®+ panel system.

Understanding the Overtopping Challenge

The Critical Problem

Overtopping is one of the most common and catastrophic failure modes in earth dams. Unlike concrete dams, earthen embankments are highly vulnerable to erosion when water flows over their crest, often resulting in rapid structural degradation and potential dam breach.

Overtopping occurs when the water level in a reservoir surpasses the height of the dam crest, resulting in water spilling over the structure. This can be caused by:

- Extreme rainfall events

- Ineffective spillway design

- Inadequate reservoir management

Once overtopping begins, the high-velocity water can erode the downstream embankment, leading to rapid failure. Various types of structures, such as embankment dams and earth embankment dams, need careful engineering to withstand natural and man-made challenges. The crest elevation of a dam plays a crucial role in determining its ability to handle excess water during extreme events.

Current Solution Limitations

Traditional approaches have focused on erosion mitigation—such as mixing chemical additives with soil to reduce erodibility—but these methods have significant drawbacks:

- Require extensive soil treatment

- Are labor-intensive

- May raise environmental or durability concerns

- Address the effects rather than preventing the root cause

Proposing the SPiRe®+ Solution: A Proactive Approach

Proposing a New Approach

Rather than mitigating erosion after overtopping begins, we propose a proactive and robust solution: prevent overtopping altogether by increasing the effective height of the dam using SPiRe®+ panel patented Fiber Reinforced Polymer (FRP) system developed for structural strengthening and protection.

[Figure 1: SPiRe®+ panels at QuakeWrap warehouse in Tucson, AZ and steps of the proposed solution]

Technology Overview

The SPiRe®+ system elevates the dam crest by several feet, effectively eliminating overtopping. As noted in a recent ACI Paper, SPiRe®+ is a truly unique product developed by Prof. Ehsani following 4 decades of innovation and product improvement. This ubiquitous product has many uses in the construction industry including the application being presented here.

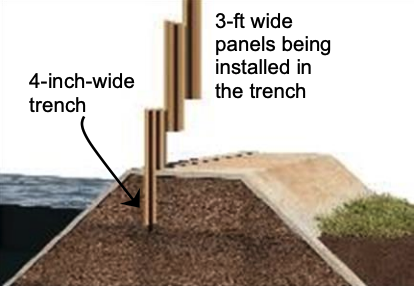

These lightweight, non-corroding panels are embedded in a 4-inch-wide trench cut into the dam’s crest and are strong enough to extend the height of the dam by up to 10 feet! Unlike conventional earth-raising methods, this approach eliminates the need for soil transport or construction traffic on the dam crest, enabling rapid deployment, even in remote or restricted-access areas.

Technical Specifications and Engineering Details

Panel Composition and Function

The patented panels are composed of Glass FRP and serve three distinct functions:

- Stay-in-place form

- Reinforcing bars

- Waterproofing membrane

Their grit-coated surfaces and integrated T-shaped profiles act as built-in reinforcement, offering a flexural strength equivalent to No. 6 Grade 60 steel bars spaced at 3.5 inches—without the need for any steel rebar.

Structural Performance

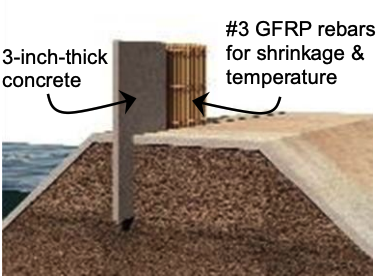

This level of reinforcement is much larger than the required steel rebars in most applications, thus eliminating the need for additional rebars. The 1.5-inch-tall T profiles require a minimum concrete thickness of 2 inches to be fully encapsulated. We are proposing a 3-inch-thick wall for this application.

Performance Data:

- In flexural tests, SPiRe®+ panels with a 3-inch concrete backing demonstrated a flexural capacity of 25.5 k-ft/ft of panel width

- Sufficient to raise the dam crest by 10 feet with a factor of safety of 2.4

- Or raise it by 4 feet with a safety factor of 38

Material Properties and Durability

- Panels are made with UV resistant vinyl ester resin

- 5mm thick flat plate portion provides excellent durability

- T profiles and interior surfaces are fully encased in concrete, never exposed to UV rays

- Optional maintenance: wall can be painted every 7-10 years

Product Data Sheets (PDS) and testing data for SPiRe®+ validate the flexural strength of walls built with 2-, 3-, and 4-inch-thick concrete over SPiRe®+ panels. Even at 3 inches, the panels exhibit over 25 k-ft/ft of flexural capacity—enough to support a wall height of 10 feet. Thicker concrete walls allow for even taller applications.

Available Configurations

We stock the 3-ft wide panels in:

- 12-foot lengths

- 18-foot lengths

- Custom lengths available for special orders

Implementation and Installation Methods

Installation Process

- Trench Preparation: A 4-inch-wide trench of desired depth (about 2 to 4 feet) is cut along the crest. This trench can be positioned a safe distance away from the edge of the crest to minimize any impact on the water tightness of the dam surface.

- Panel Placement: The 3-ft wide panels are placed inside the trench, extending the desired height above the crest. The panels include 4-inch-wide overlapping edges, sealed with rubber strips to create a continuous, watertight stay-in-place form.

- Sealing and Reinforcement: If desired, additional self-tapping screws may be added to the overlap region for redundancy.

- Foundation Concrete: The trench is filled with concrete and allowed to set. This stiff foundation at the base along with the stiffness of the SPiRe®+ panels eliminates the need for bracing the upper portion of the wall, significantly simplifying the completion of the project.

- Wall Construction: Since the panels resist tensile forces from upstream water pressure, no reinforcement is needed on the downstream face of the wall. A flat, removable & reusable form (plywood or GFRP) is connected to the SPiRe®+ panel to form a wall of desired thickness.

- Final Concrete Pour: Concrete for casting the wall and foundation can be delivered in ready-mix trucks or mixed onsite in smaller batches when access is limited. Horizontal #3 GFRP bars can be attached to the T-flanges using special clips at 12–16 inch spacing for temperature and shrinkage control.

- Form Removal: The temporary flat forms on the downstream face of the wall will be removed, leaving the concrete surface visible.

Proven Applications and Track Record

Developer Credentials

The SPiRe®+ system was invented by Dr. Mo Ehsani, Professor Emeritus of Civil Engineering at the University of Arizona and President of QuakeWrap, Inc. A pioneer in FRP repair technologies, Dr. Ehsani holds over 20 U.S. patents in this field. One of his patented systems, PileMedic®, is the only system approved by the USACE for repair of submerged piles following extensive testing by the U.S. Army ERDC.

Real-World Applications

Though introduced just under two years ago from the experience we gained during a marine pier repair project at the Port of Galveston, SPiRe®+ has already been widely adopted. Current applications include repair of:

- Timber seawalls

- Bridge pier walls

- Corroded steel sheet piles

- Deteriorated concrete slabs

A closely related application is for increasing the elevation of seawalls to protect against rising sea levels—currently being implemented on multiple Florida projects.

Key Benefits and Advantages

By addressing the root cause—overtopping—rather than just its effects, this solution offers a transformative upgrade for existing earth dams. Key benefits include:

- Increased storage capacity by raising the dam elevation

- Fast, non-invasive installation

- Use of durable, non-corroding FRP materials

- Elimination of steel reinforcement and corrosion concerns

- Creation of an impervious, watertight barrier

- Minimal impact on dam operations during installation

- Suitable for remote or restricted-access areas

Comprehensive Dam Safety and Overtopping Prevention

Design Improvements for Enhanced Safety

Increased Freeboard: Increasing the height of the dam (freeboard) provides additional capacity to manage unexpected inflows. This can be achieved through traditional earthwork or advanced materials such as SPiRe®+ panels that extend the dam crest safely and efficiently.

Optimized Spillways: With earth dams, spillways must be adequately designed and maintained to handle peak flow conditions. Consideration should be given to both primary and auxiliary spillways to ensure that excess water can be safely released.

Emergency Overflow Sections: Designing emergency overflow sections or channels can provide a controlled path for overtopping flows, minimizing the risk of erosion and failure.

Monitoring and Early Warning Systems

Hydro-Meteorological Monitoring: Implementing advanced weather and hydrological monitoring systems can predict extreme weather events, giving time to manage reservoir levels proactively.

Surveillance and Sensors: Installing sensors along the dam to monitor seepage, deformation, and water levels can provide early warnings of potential overtopping scenarios.

Maintenance and Rehabilitation

Regular Inspections: Conducting regular inspections ensures that the dam and its components, such as spillways and drainage systems, are in good condition and functioning effectively. Learning from dam failures in the past has highlighted the importance of rigorous inspection and regular dam repair to ensure these structures remain robust in the face of potential threats.

Reinforcement and Repairs: Use materials such as reinforced concrete or geosynthetics to strengthen and repair any identified weak points in the dam structure. Earthen dams, in particular, demand specific maintenance practices due to their composition.

Community Engagement and Emergency Planning

Public Awareness Programs: Engaging local communities about the role and risks associated with earth dams can promote a culture of safety and preparedness.

Emergency Response Plans: Developing comprehensive emergency response plans ensures rapid and coordinated action in the event of potential dam safety issues.

Broader Context: Critical Infrastructure Protection

Understanding Flood Protection Systems

Dams are critical infrastructures that require meticulous attention to ensure their safety and functionality. Moreover, levees and levee systems are essential in providing additional protection against flooding. A levee system consists of engineered earthen embankments designed to contain floodwaters and protect wet areas from floods. These flood protection barriers work in conjunction with earth dams to provide comprehensive flood management.

Levee systems serve as the first line of defense for communities located in flood-prone areas, creating flood protection walls that channel water away from populated regions. However, both embankment dams and levees can suffer from overtopping if not properly maintained or designed, making overtopping protection a critical consideration for both types of infrastructure.

Earth Dam Challenges and Solutions

Earth dams are crucial structures designed to store water for various purposes, including irrigation, water supply, and flood control. However, one significant challenge they face is dam overtopping, which can lead to overtopping failuresand catastrophic downstream flooding. Understanding and implementing measures to prevent overtopping is essential to maintaining the structural integrity and safety of these dams.

Earthen dams face unique challenges including surface erosion, potential seismic landslides, and the need for specialized earth dam sealant and earth dam sealer applications. Working with a qualified dam repair contractor is essential for addressing these issues and maintaining dam crest elevation at appropriate levels.

The risks associated with dam overtopping risk must be understood and mitigated by implementing advanced technologies and engineering solutions. By focusing on these areas, the risk of catastrophic dam failures can be significantly reduced, thereby safeguarding communities and environments downstream. A significant risk to these structures is dam overtopping, which can compromise the integrity of both concrete and earth-rockfill dams.

Reinforced Earth Technology

Modern solutions like SPiRe®+ represent advances in reinforced earth technology, providing flood protection panels that can be integrated into existing earthen embankment structures. This approach offers superior overtopping protection compared to traditional methods.

In essence, understanding dam safety involves not only engineering but also a strong commitment to learning from past failures and continuously improving practices. By addressing aspects like dam overtopping risk, improving dam crest elevation measurements, and reinforcing earth-rockfill dams, we can enhance the resilience and reliability of these crucial infrastructures.

Conclusion and Next Steps

We welcome the opportunity to collaborate with the U.S. Army Corps of Engineers (USACE) on a pilot demonstration to validate this innovative solution under real-world conditions. The SPiRe®+ panels are available in our warehouse in Tucson and the technology is ready for immediate installation.

This revolutionary approach represents a paradigm shift from reactive erosion mitigation to proactive overtopping prevention, offering dam operators a robust, durable, and rapidly deployable solution for enhancing dam safety and performance.

Frequently Asked Questions

A levee system is a network of engineered earthen embankments and flood protection barriers designed to prevent flooding by containing river water within designated channels. Unlike earthen dams that store water, levee systems are built alongside rivers to protect adjacent land from overtopping failures during high-water events.

Flood protection panels like SPiRe®+ can be integrated with existing earth embankment structures to increase dam crest elevation and provide enhanced overtopping protection. These panels serve as modern flood protection wallsthat work in conjunction with traditional earth dam sealant and earth dam sealer applications.

Overtopping failures in earthen dams typically result from inadequate dam crest elevation, extreme weather events, poor spillway design, or surface erosion that compromises the structural integrity. Additionally, seismic landslides can alter the dam profile and increase dam overtopping risk.

A qualified dam repair contractor should be contacted when signs of surface erosion, seepage, or structural damage are observed in earth dams. Regular maintenance including application of earth dam sealer products and assessment of overtopping risk should be performed by experienced professionals.

Wet areas that are naturally prone to flooding benefit significantly from comprehensive flood protection systems. These areas require both levee systems and properly maintained earthen embankments to protect from floods, creating safe zones for communities and infrastructure.

Specialized materials applied to earthen embankment surfaces to prevent water infiltration and reduce surface erosion.

Engineering technique that combines soil with tensile reinforcing elements to create stable earth embankment structures.